Contact Us

Applications of Aerogel in the Construction Industry

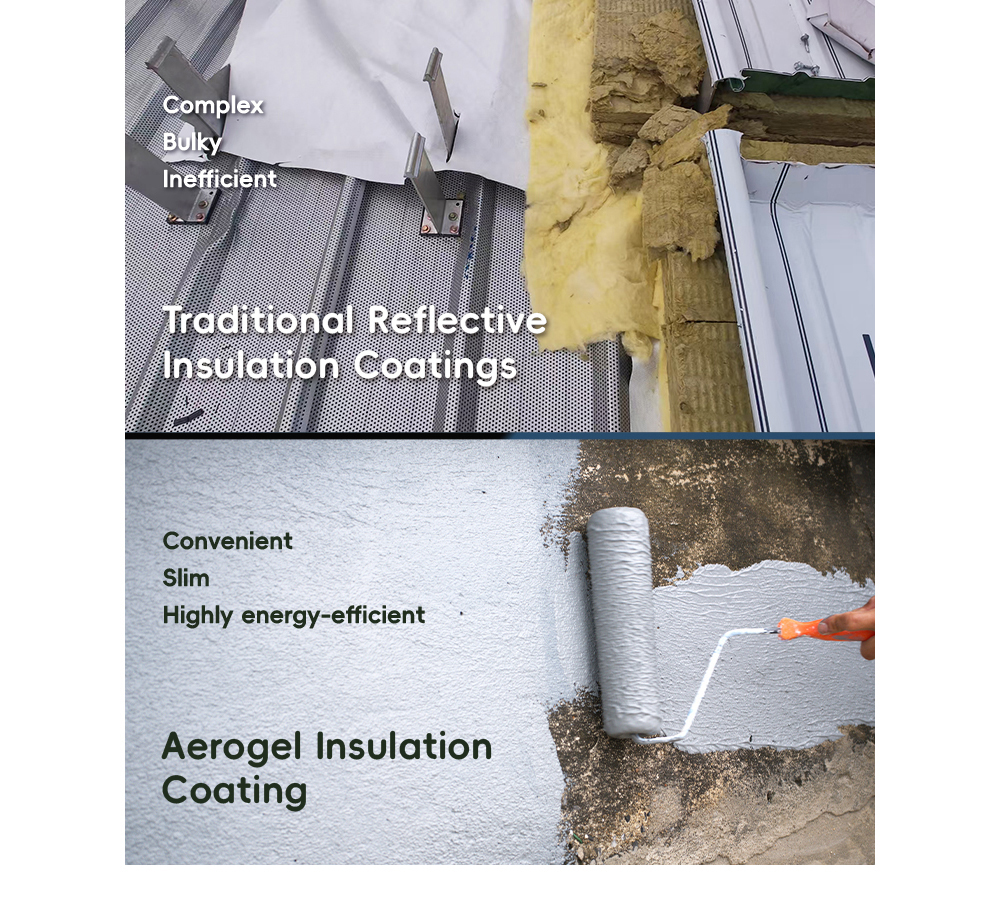

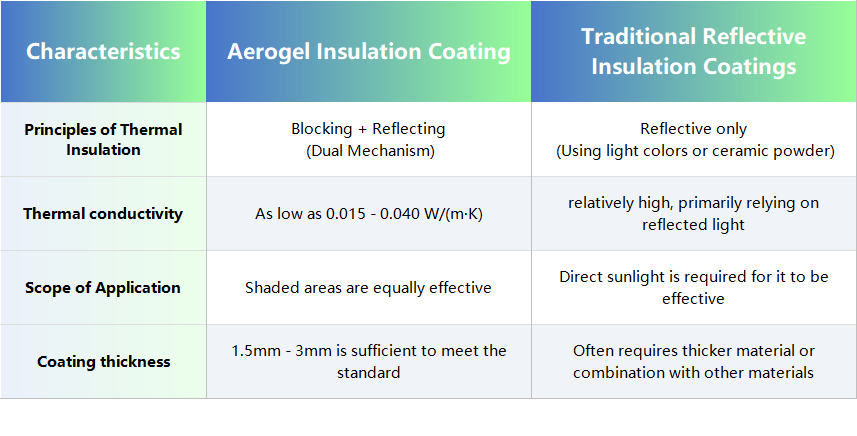

Aerogel, once a cutting-edge material primarily used in aerospace and high-tech industries, is now finding increasingly diverse applications. In the construction sector, applications have evolved from early panel and felt products to today’s more flexible aerogel insulation coatings. These coatings achieve both brushability and thermal insulation by uniformly dispersing aerogel powder (typically silica aerogel) within a water-based resin matrix.

Core Application Scenarios:

Addressing Thermal Bridges and Space Constraints Unlike bulky insulation boards, aerogel coatings excel through their ultra-thin profile and adaptability to irregular shapes.

- Energy retrofits for existing buildings: From 2024-2025, numerous renovation projects in older communities will adopt aerogel coatings. Since existing building facades often lack structural capacity for thick insulation layers, spraying a 2-3mm aerogel coating achieves significant cooling effects.

- Thermal bridge blocking: Beams, columns, and window/door frames in buildings are prone to “thermal bridges” that cause condensation and mold growth. Aerogel coatings can be applied like conventional paint to these intricate areas, effectively blocking heat transfer.

- Metal Roofing and Storage Tanks: In industrial buildings, aerogel coatings are extensively sprayed onto color-coated steel roofs. Experimental data shows that under intense sunlight, the inner surface temperature of aerogel-coated roofs can be reduced by 15°C to 20°C.

Latest Technological Developments in 2025

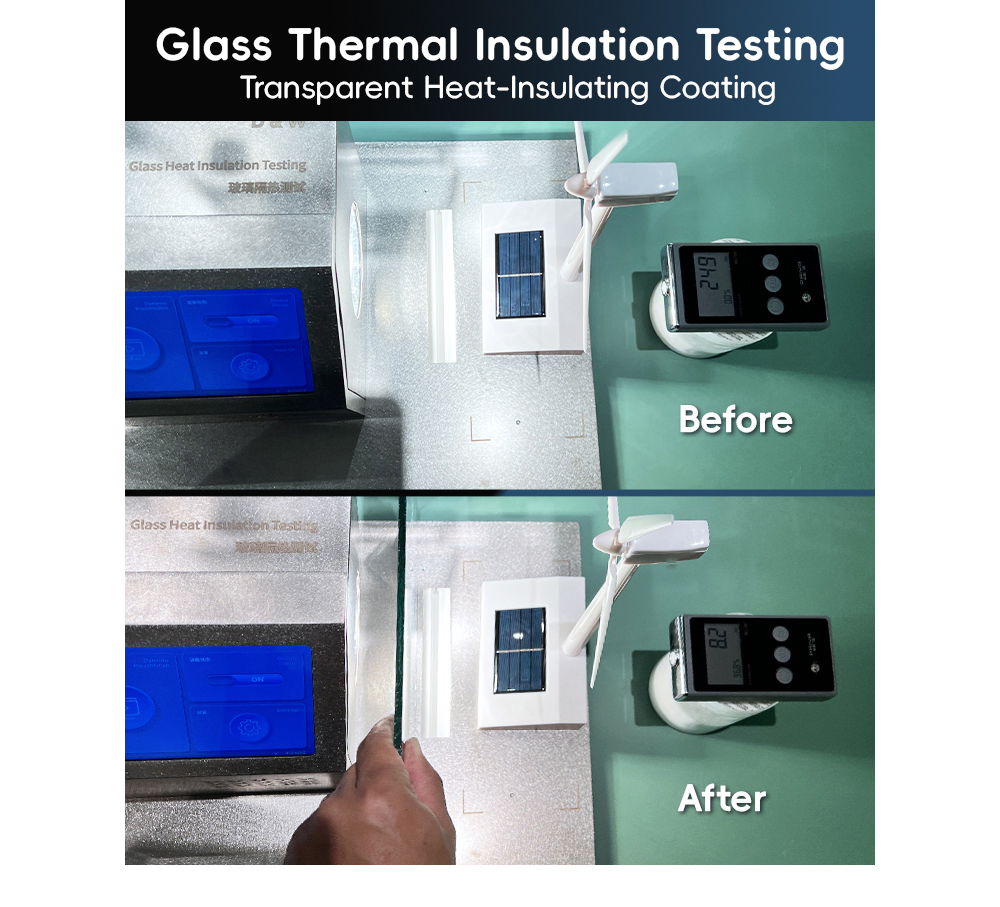

- Transparent Insulation Coatings: Scientists have developed highly transparent aerogel coatings that can be directly sprayed onto window glass. These coatings allow visible light to pass through while reflecting over 90% of infrared heat radiation.

- Integrated Functionality: The latest aerogel coatings no longer serve solely as insulation. They now incorporate Class A fire resistance, strong hydrophobic (water-repellent) properties, and UV protection. Mainstream products on the 2025 market can now withstand outdoor exposure for up to 20 years without peeling or yellowing.

- Atmospheric Pressure Drying Mass Production: As “atmospheric pressure drying” technology matures, aerogel powder costs are decreasing. This directly drives down the price of building-grade aerogel coatings, transforming them from “space-grade exclusives” to “civilian-accessible solutions.”